Perché i termistori NTC vengono utilizzati in serie | Guida alla protezione dalle sovratensioni?

Nov 04, 2025Nel ciclo di funzionamento dei dispositivi elettronici, il momento di accensione è il più critico. Quando viene applicata l'alimentazione, una corrente elevata si riversa nei condensatori di filtro, generando una sovratensione di spunto che può essere decine di volte superiore alla normale corrente di funzionamento. Questa sovratensione improvvisa può danneggiare componenti come ponti raddrizzatori, fusibili e contatti dei relè, accelerando al contempo l'invecchiamento del sistema e riducendo la durata complessiva delle apparecchiature.

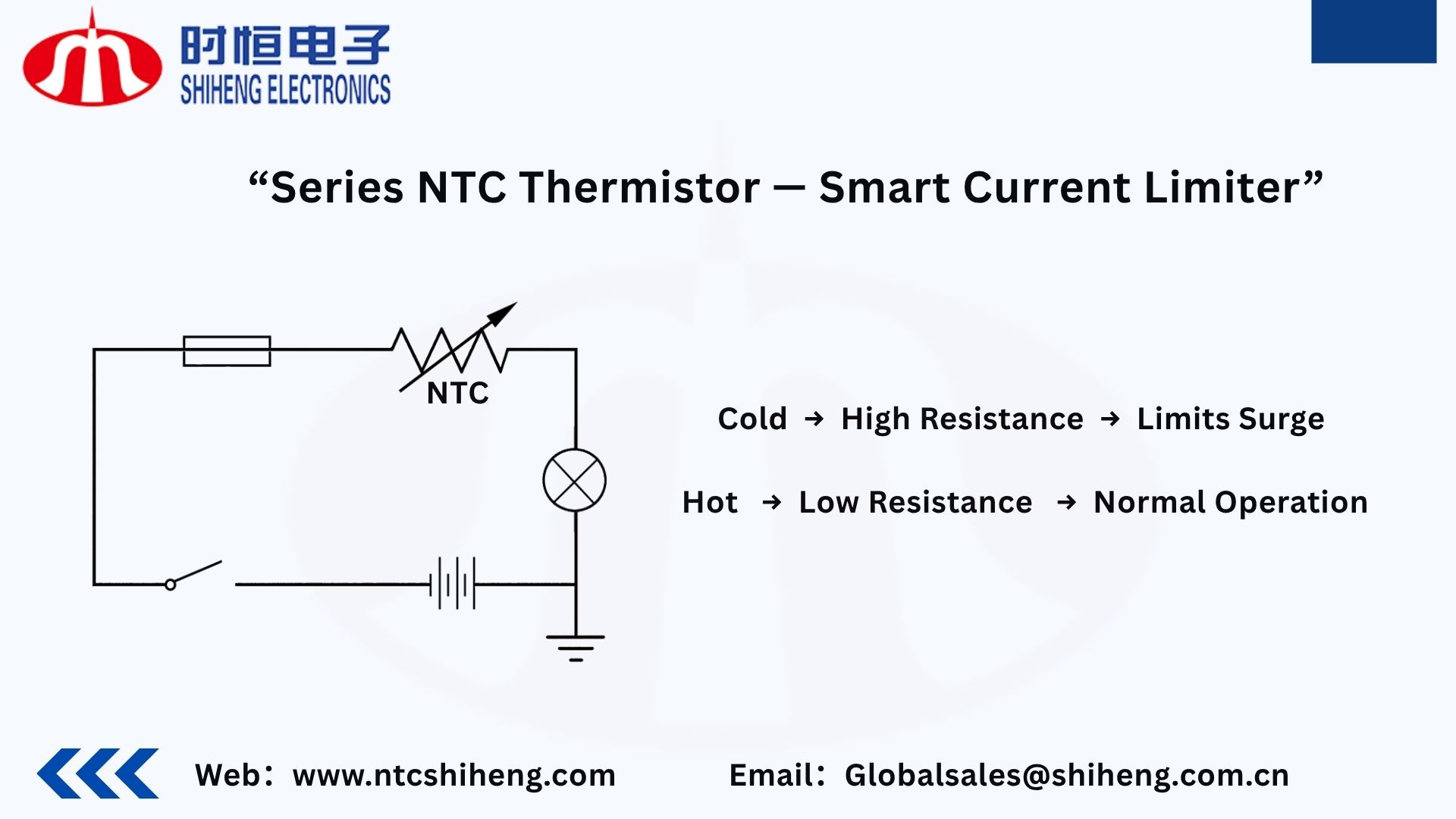

Termistori NTC per correnti di spunto sono i componenti chiave che proteggono da questa sovracorrente. Ma perché devono essere sempre collegati in serie? Analizziamolo attraverso quattro aspetti: principio, processo di funzionamento, vantaggi e limiti.

I. Principio fondamentale: coefficiente di temperatura negativo e logica in serie.

I termistori NTC (Negative Temperature Coefficient) presentano una caratteristica fondamentale: la loro resistenza diminuisce all'aumentare della temperatura.

A temperatura ambiente (stato freddo), la loro resistenza è relativamente elevata. Una volta che la corrente inizia a fluire, il dispositivo si riscalda, la sua temperatura aumenta e la sua resistenza diminuisce bruscamente, costituendo la base della limitazione dinamica della corrente. In qualsiasi circuito, il modo più semplice per limitare la corrente è aggiungere un resistore in serie. Corrente di spunto La tecnologia NTC combina questo principio con la sensibilità alla temperatura, agendo come una "resistenza variabile intelligente" quando collegata in serie alla linea di alimentazione principale. Fornisce una protezione con limitazione di corrente durante l'avvio, senza praticamente alcuna perdita durante il funzionamento a regime.

II. Funzionamento in serie: dalla “limitazione di corrente” al “funzionamento a bassa resistenza”.

Quando il dispositivo viene acceso per la prima volta, l'NTC è freddo e altamente resistivo. Questo limita la corrente di spunto, proteggendo il ponte raddrizzatore, i condensatori di filtro e gli altri componenti a valle.

Man mano che l'NTC si riscalda a causa del flusso di corrente, la sua resistenza diminuisce rapidamente fino a pochi decimi di ohm o meno, consentendo il normale flusso di corrente con una perdita di potenza minima. Questo processo prevede due fasi distinte:

Questa regolazione automatica non richiede alcun circuito di controllo esterno, offrendo un meccanismo di protezione soft-start semplice e affidabile per i sistemi elettronici.

III. Principali vantaggi della configurazione in serie.

IV. Limitazioni e considerazioni progettuali.

(1) Tempo di recupero.

Dopo lo spegnimento, l'NTC deve raffreddarsi per riacquistare la sua elevata resistenza. Se il dispositivo si riavvia troppo rapidamente, il termistore rimane in uno stato di bassa resistenza, perdendo la sua capacità di protezione da sovratensioni.

→ Soluzione: utilizzare un progetto di bypass del relè: una volta che il sistema si stabilizza, il relè cortocircuita l'NTC, migliorando l'affidabilità ed eliminando la perdita di potenza in stato stazionario.

(2) Perdita di calore e progettazione della potenza.

Anche durante il funzionamento a regime, viene generata una piccola quantità di calore. I progettisti devono assicurarsi che l'NTC funzioni entro il suo intervallo di potenza nominale e prevedere un'adeguata ventilazione o dissipazione del calore del PCB.

(3) Sensibilità alla temperatura ambiente.

La resistenza iniziale varia significativamente con la temperatura. In ambienti molto freddi, l'avviamento può essere difficoltoso a causa dell'elevata resistenza; in condizioni di caldo, la resistenza potrebbe essere troppo bassa per limitare efficacemente la corrente.

→ Soluzione: selezionare un NTC con un valore B adeguato oppure utilizzare un circuito di avviamento a corrente costante per applicazioni ad ampio range di temperatura.

V. Riepilogo

Il collegamento in serie del tipo di potenza Termistori NTC è fondamentale per le loro prestazioni di limitazione delle sovratensioni:

Questa combinazione rende i termistori NTC una delle soluzioni di avviamento graduale più economiche e affidabili nell'elettronica moderna.

Nanjing Shiheng Electronics Co., Ltd. è specializzata nella ricerca e sviluppo e nella produzione di termistori NTC e sensori di temperatura. La nostra gamma completa di prodotti di potenza: MF72, MF73T, MF74, MF75— copre dimensioni da Φ3 mm a Φ40 mm, soddisfacendo le esigenze di piccoli elettrodomestici e sistemi industriali di potenza. Con elevata precisione, eccellente stabilità e ampia adattabilità, Shiheng Electronics offre soluzioni di protezione dalle sovratensioni sicure, efficienti e durature per clienti in tutto il mondo.